In the expansive domain of eCommerce, mastering the intricacies of inventory management stands as a pivotal challenge—one that separates adept enterprises from those grappling with operational complexities.These complexities are not mere hurdles; they represent opportunities for innovation and strategic prowess. From anticipating market shifts to orchestrating global logistics, the adept handling of this labyrinthine landscape defines the triumph of eCommerce enterprises.

Reasons to Handle Inventory Challenges:

1. Cost Control: Effective inventory management helps control costs associated with holding excess inventory, such as storage expenses, depreciation, insurance, and obsolescence costs.

2. Customer Satisfaction: Maintaining optimal inventory levels ensures products are available when customers demand them, enhancing customer satisfaction and loyalty.

3. Cash Flow Management: Balancing inventory levels prevents tying up excessive capital in inventory, allowing for better cash flow management and investment opportunities.

4. Operational Efficiency: Streamlined inventory processes reduce inefficiencies, improve order fulfillment times, and enhance overall operational efficiency.

5. Competitive Advantage: Efficient inventory management enables businesses to respond quickly to market demands, gain a competitive edge, and adapt to changing trends.

Learn about inventory management plugins here.

Key Challenges in Inventory Management:

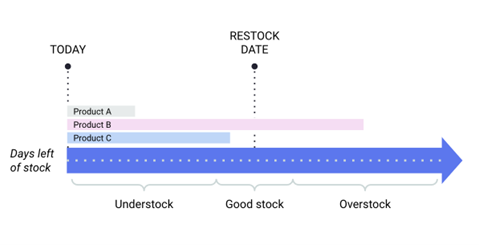

Challenge #1: Overstocking and Understocking

Managing Inventory Levels Without Capital Constraints or Stockouts

Balancing act is the name of the game in inventory management. Ensuring adequate stock to meet demand without tying up excessive capital or risking stockouts is a perpetual challenge.

Strategies to Tackle This Challenge:

- Data-Driven Forecasting: Leveraging historical sales data and market trends to forecast demand accurately. This informs inventory decisions, preventing both overstocking and understocking scenarios.

- Dynamic Optimization Tools: Implementing agile, real-time inventory adjustment solutions. These tools allow swift adaptations based on evolving demand patterns, ensuring inventory levels stay aligned with market needs.

- Supplier Collaboration: Fostering robust relationships with suppliers for a responsive supply chain. This collaboration facilitates quick adjustments in inventory to meet fluctuations in demand, enhancing agility in inventory management.

- Order Fulfillment Optimization: Streamlining order fulfillment processes to minimize lead times. Efficiency in fulfilling orders reduces the likelihood of stockouts while maintaining optimal inventory levels.

Real-World Tools to Implement Strategies:

- TradeGecko: A comprehensive inventory management platform that integrates with eCommerce platforms, aiding in data-driven decision-making and inventory optimization.

- Zoho Inventory: An intuitive tool that enables data-driven forecasting, streamlining inventory management, and facilitating effective supplier collaboration.

- Fishbowl Inventory: A robust solution offering inventory tracking, demand forecasting, and order management, empowering businesses to optimize their inventory operations.

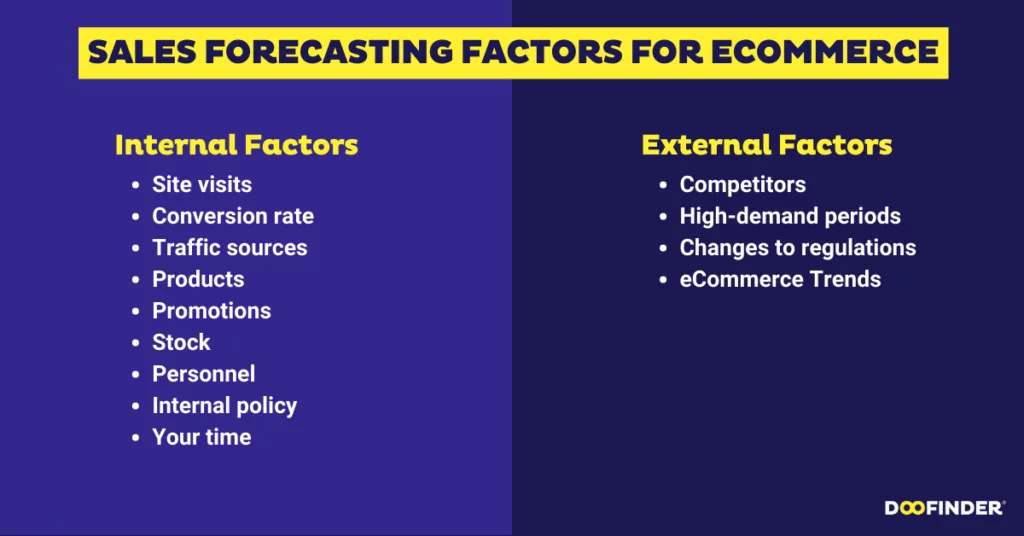

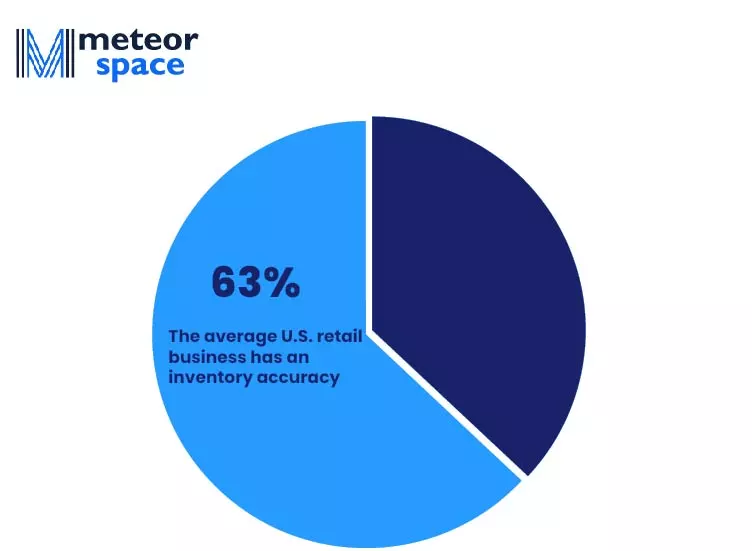

Challenge #2: Forecasting Accuracy

Source: Doofinder

Predicting Consumer Behavior Amidst Market Fluctuations

Forecasting accuracy in the face of volatile market demand poses a significant challenge, requiring strategies that align predictive capabilities with dynamic market shifts.

Strategies to Improve Accuracy:

- Data Analytics: Leveraging historical data and predictive analytics to gain actionable insights. Utilizing quantitative data aids in forecasting market trends and consumer behavior patterns.

- Qualitative Insights: Collaborating with marketing and sales teams to gather qualitative data. Insights from these teams provide a holistic view of market dynamics, complementing quantitative analysis for more accurate predictions.

- Scenario Planning: Conducting scenario-based planning to prepare for various market scenarios. This proactive approach enhances adaptability, enabling swift adjustments in forecasting models to align with changing market conditions.

Real-World Tools for Implementation:

- Tableau: A robust data visualization tool that assists in analyzing historical data and creating predictive models, enhancing forecasting accuracy.

- SAS Predictive Analytics: Offering advanced predictive analytics capabilities, SAS aids in leveraging data for accurate forecasting and strategic decision-making.

- IBM Planning Analytics: Equipped with scenario planning features, IBM Planning Analytics empowers businesses to create adaptable forecasting models aligned with dynamic market conditions.

Challenge #3: Real-Time Tracking

Maintaining Accurate Inventory Oversight, Especially for High-Value Goods

The challenge of precision monitoring demands robust strategies for real-time tracking, particularly for high-value inventory items where accuracy is paramount.

Strategies to Enhance Tracking Precision:

- Advanced Technologies: Implementing cutting-edge solutions like RFID (Radio-Frequency Identification) or IoT (Internet of Things) sensors for granular inventory tracking. These technologies offer real-time insights into inventory movements, ensuring accurate monitoring, especially for high-value items.

- Integrated Systems: Utilizing inventory management systems integrated with logistics platforms. This integration streamlines data flow, enabling seamless real-time updates on inventory movements across the supply chain.

- Data Analytics: Leveraging data analytics to interpret real-time tracking data. Analyzing this data enables businesses to identify bottlenecks or inefficiencies in inventory management, facilitating proactive decision-making.

Real-World Tools for Implementation:

- ShipHero: ShipHero offers comprehensive inventory and order management solutions with real-time tracking capabilities, ensuring precision in inventory oversight.

- Oracle NetSuite: Oracle NetSuite provides a unified platform integrating inventory and supply chain management, offering real-time tracking functionalities for enhanced oversight.

Challenge #4: Inventory Visibility

Maintaining Constant Visibility Across Multiple Channels

The challenge lies in ensuring comprehensive oversight of inventory across various channels, demanding strategies that offer real-time insights and unify data flow for seamless visibility.

Strategies to Enhance Inventory Visibility:

- Robust Systems: Implementing specialized inventory management software that provides real-time insights into inventory levels and movements. These systems offer centralized control and visibility across multiple channels.

- Advanced Technologies: Leveraging advanced technologies like RFID or IoT for automated inventory tracking. These technologies enable automated, accurate tracking across different channels, ensuring real-time visibility.

- Unified Data Flow: Integrating inventory management systems with ERP (Enterprise Resource Planning) software for consistency in data flow. This integration ensures that inventory data is synchronized and consistent across the entire enterprise ecosystem.

Real-World Tools for Implementation:

- DEAR Inventory: DEAR Inventory offers comprehensive inventory management solutions, providing real-time visibility and control over inventory across various channels.

- TradeGecko: TradeGecko offers a centralized platform for inventory management, enabling businesses to have seamless visibility and control over inventory across multiple channels.

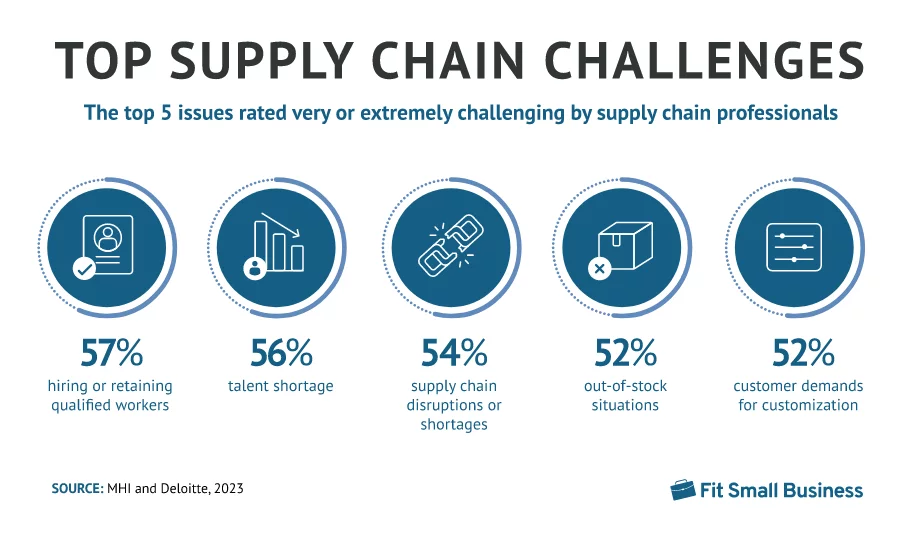

Challenge #5: Supply Chain Disruptions

Source: Fitsmallbusiness

Handling Supplier Issues, Delayed Shipments, and Logistical Complexities

The challenge lies in managing vulnerabilities to disruptions within the supply chain, necessitating strategies that mitigate risks through diversification, proactive risk management, and transparent collaboration.

Strategies to Mitigate Disruptions:

- Diversified Suppliers: Cultivating relationships with multiple suppliers to diversify risks. Having alternative sources mitigates the impact of disruptions from a single supplier, ensuring continuity in the supply chain.

- Risk Management: Implementing robust risk management practices such as contingency planning and scenario analysis. This proactive approach prepares businesses to navigate potential disruptions with pre-defined strategies.

- Collaboration: Fostering transparent communication and collaboration with suppliers and partners. Establishing clear channels for information exchange enhances responsiveness and agility in handling disruptions.

Real-World Tools for Implementation:

- Kinaxis RapidResponse: Kinaxis RapidResponse offers end-to-end supply chain visibility and risk mitigation tools, enabling businesses to proactively manage disruptions and optimize their supply chains.

- Resilinc Supply Chain Risk Management: Resilinc offers supply chain risk management solutions that provide visibility into potential disruptions, allowing businesses to take proactive measures to mitigate risks.

Neglecting Inventory Challenges:

1. Increased Costs:

- Effect: Overstocking leads to higher holding costs, while stockouts result in lost sales and potential customer dissatisfaction.

- Impact: Increased costs diminish profitability and can lead to budget constraints in other operational areas.

2. Poor Customer Service:

- Effect: Inadequate inventory levels result in delayed deliveries or unfulfilled orders.

- Impact: Dissatisfied customers may switch to competitors, tarnishing the company’s reputation and reducing customer loyalty.

3. Capital Constraints:

- Effect: Excessive inventory ties up capital, impacting cash flow and limiting investments.

- Impact: Restricted access to funds hampers growth opportunities and limits the ability to seize favorable business prospects.

4. Operational Disruptions:

- Effect: Supply chain disruptions and inefficient inventory processes lead to operational delays.

- Impact: Delays affect production schedules, increase lead times, and may strain relationships with suppliers and customers.

5. Market Disadvantages:

- Effect: Inability to adapt to market conditions or meet customer demands promptly.

- Impact: Loss of market share, decreased competitiveness, and reduced profitability due to an inability to capitalize on market opportunities.

Companies That Suffered Inventory Mnaagement Setbacks:

A. Zara (Inditex Group):

Challenge: Zara faced the challenge of managing a vast and rapidly changing inventory due to its fast fashion model. The company aimed to minimize stockouts while avoiding excessive inventory build-up.

Innovative Approach:

- Fast Production and Distribution: Zara revolutionized the fashion industry by reducing the time between design, production, and store shelves. Their vertically integrated supply chain allowed for quick manufacturing and distribution.

- Data-Driven Inventory Management: They used sophisticated data analytics to predict trends, optimize inventory levels, and manage production based on real-time demand.

Outcome:

- Zara’s agile inventory management strategy led to reduced markdowns, minimized excess inventory, and increased responsiveness to changing consumer preferences, contributing significantly to their success in the retail industry.

B. Amazon:

Challenge: Amazon faces the challenge of managing an extensive and diverse inventory across various product categories and fulfillment centers while ensuring timely deliveries.

Innovative Approach:

- Advanced Technology: Amazon utilizes cutting-edge technology, including AI-driven demand forecasting, robotics in warehouses, and predictive analytics, to optimize inventory levels and streamline logistics.

- Dynamic Inventory Management: They employ a just-in-time inventory model, where items are stocked based on real-time demand, reducing excess inventory and storage costs.

Outcome:

- Amazon’s efficient inventory management and fulfillment processes have enabled them to offer fast and reliable shipping, maintain a vast product selection, and adapt swiftly to changing consumer demands, solidifying their position as an e-commerce giant.

C. Walmart:

Challenge: Walmart faced challenges in managing inventory across a vast network of stores, ensuring the right products were available at the right locations while minimizing excess stock.

Innovative Approach:

- Supply Chain Optimization: Walmart developed a sophisticated supply chain system that emphasized collaboration with suppliers and implemented advanced logistics technologies.

- Inventory Tracking and Management: They introduced inventory-tracking systems, like RFID technology, to monitor stock levels in real-time, reducing instances of overstocking and stockouts.

Outcome:

- Walmart’s focus on supply chain efficiency and innovative inventory management allowed them to optimize inventory levels, reduce costs, and maintain competitive pricing, contributing to their success as a retail leader.

D. Toyota:

Challenge: Toyota faces inventory challenges in managing a complex supply chain, ensuring a balance between parts availability and minimizing excessive inventory in their production processes.

Innovative Approach:

- Just-in-Time (JIT) Manufacturing: Toyota pioneered the JIT inventory system, where components are delivered precisely when needed, reducing excess inventory and waste.

- Kanban System: They implemented a visual signaling system (Kanban) to manage inventory levels, enabling efficient production and reducing inventory carrying costs.

Outcome:

- Toyota’s innovative inventory management methods revolutionized the automotive industry, allowing them to maintain lean inventories, minimize production disruptions, and deliver high-quality vehicles with efficiency.

E. Procter & Gamble (P&G):

Challenge: P&G manages a vast portfolio of consumer goods, facing challenges in demand volatility, product lifecycle management, and optimizing inventory across global markets.

Innovative Approach:

- Collaborative Forecasting: P&G collaborates closely with retailers, using shared data to enhance demand forecasting accuracy and align inventory levels with market demands.

- Product Innovation and Portfolio Management: They strategically manage product portfolios, focusing on innovation and trimming less profitable product lines to streamline inventory.

Outcome:

- P&G’s robust inventory management strategies have helped them maintain optimal stock levels, reduce excess inventory write-offs, and drive innovation while meeting consumer needs across diverse markets.

Conclusion:

Inventory management challenges are diverse and dynamic, requiring proactive strategies and adaptable solutions. Employing a combination of technology, data analysis, and streamlined processes is crucial to effectively address these challenges and optimize inventory operations.

FAQs on Inventory Management Challenges:

How can businesses overcome demand forecasting challenges?

Employ data analytics, historical sales data, market trends analysis, and collaborate closely with sales and marketing teams to enhance demand forecasting accuracy.

What strategies help mitigate supply chain disruptions?

Diversifying suppliers, maintaining buffer inventory, establishing strong communication, and utilizing risk management strategies like supply chain mapping can mitigate disruptions.

How can companies optimize inventory without overstocking or stockouts?

Adopt lean inventory practices, employ just-in-time (JIT) inventory systems, utilize demand forecasting tools, and implement efficient replenishment strategies.