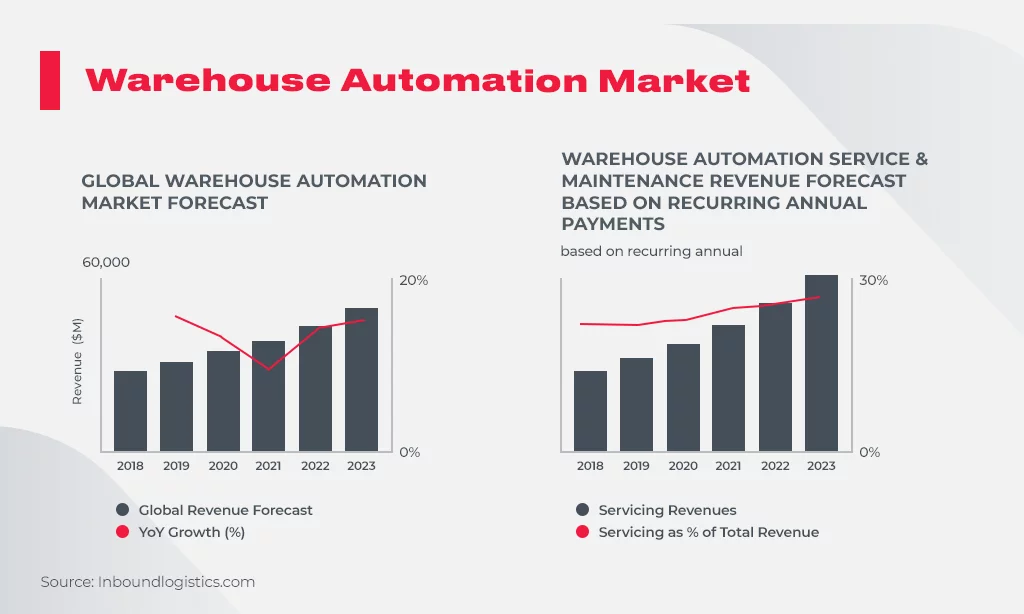

The landscape of e-commerce undergoes constant evolution, with warehouse automation standing out as one of the most revolutionary changes in recent years. As online shopping experiences unprecedented growth, the traditional methods of storing, sorting, and shipping goods are undergoing a significant transformation. In this exploration, we will delve into the profound impact of warehouse automation on e-commerce and how businesses utilize it to improve efficiency and customer satisfaction.

What is Warehouse Automation?

Warehouse automation is the fusion of technology, machinery, and advanced software aimed at streamlining various tasks within warehouses. From employing AI-driven robots for product picking to implementing conveyor systems for seamless transportation, automation seeks to enhance the efficiency and accuracy of warehouse operations.

Best Practices for Implementing Warehouse Automation in E-commerce

- Phased Implementation: Transitioning to automation should occur in stages, allowing for testing and adjustment of new systems. This approach minimizes disruptions and ensures alignment with business goals.

- Regular Maintenance: Scheduled maintenance checks are essential to preempt machinery breakdowns and software glitches, ensuring uninterrupted operations.

- Employee Training: Investing in comprehensive training for the workforce enables them to effectively operate and troubleshoot automated systems, maximizing efficiency and minimizing downtime.

- Invest in Scalability: Automation solutions should be flexible enough to accommodate fluctuating e-commerce demands, including peak periods and regular operational needs.

- Data Protection: With increased automation comes heightened data collection. Robust cybersecurity measures safeguard business operations and customer information from potential threats.

Essential Hardware and Software in E-commerce Warehouse Automation:

- Robotic Process Automation (RPA): Advanced AI-powered robots can perform tasks autonomously, making decisions based on real-time data to optimize warehouse operations.

- Automated Storage & Retrieval Systems (AS/RS): These systems maximize storage efficiency and predict retrieval patterns based on order histories, ensuring fast access to frequently requested items.

- Warehouse Management Systems (WMS): Modern WMS incorporate AI and machine learning for inventory management, demand forecasting, and warehouse optimization, streamlining operations and reducing costs.

- IoT Sensors: Sophisticated sensors monitor inventory, device health, and energy consumption, contributing to operational efficiency and sustainability.

- Drones: Equipped with cameras and sensors, drones provide real-time surveillance and assist in identifying operational bottlenecks or security threats.

Learn about warehouse management here.

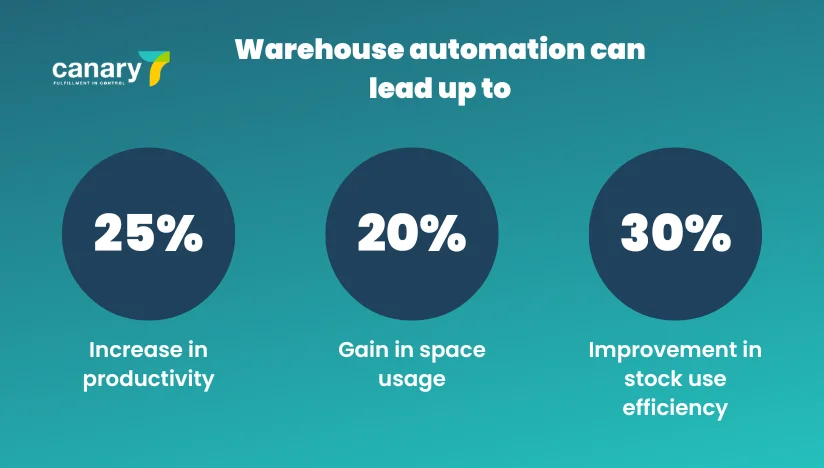

Benefits Reaped by E-commerce Businesses with Warehouse Automation:

- Efficiency Surge: Automated warehouse systems operate continuously, ensuring faster shipping times and meeting customer expectations for swift delivery.

- Error Minimization: Automation reduces human error, leading to accurate deliveries and decreased costs associated with returns and customer service.

- Cost Reduction: Despite initial investment, automation leads to long-term savings through reduced labor costs, waste reduction, and optimized operations.

- Elevated Customer Satisfaction: Timely and accurate deliveries, along with real-time tracking, enhance the customer experience and foster loyalty.

- Adaptability: Automated systems enable e-commerce businesses to quickly adapt to market changes, maintaining agility and competitiveness in the industry.

Warehouse automation refers to a broad spectrum of technologies aimed at streamlining warehouse processes through automation. It encompasses both hardware and software solutions designed to enhance the efficiency and productivity in warehouse operations.

Hardware solutions include various types of machines utilized within warehouses for storing and transporting goods. These machines include:

- Collaborative mobile robots, also known as cobots, which assist workers in tasks such as picking and transporting items within the warehouse.

- Pick-to-light systems, which use visual cues to guide workers to the location of items to be picked, reducing picking errors and improving efficiency.

- AS/RS, which utilize automated cranes or shuttles to store and retrieve goods from storage locations, maximizing space utilization and retrieval speed.

- Sortation systems, which automatically sort items based on predefined criteria, facilitating order fulfillment and shipping processes.

- Internet of Things (IoT) devices, which collect and transmit data from various sensors and devices within the warehouse, enabling real-time monitoring and optimization of operations.

On the other hand, software solutions play a crucial role in warehouse automation by providing tools for warehouse management. These software tools streamline various aspects of warehouse operations, including:

- Data entry and management, automating tasks such as inventory tracking, order processing, and shipment tracking.

- Analytics and reporting, providing insights into warehouse performance, inventory levels, and order fulfillment metrics.

- Inventory management, optimizing inventory levels, and storage locations to minimize stockouts and improve order accuracy.

- Workflow automation, automating repetitive tasks and workflows to reduce manual intervention and improve efficiency.

Top Tools for Warehouse Automation:

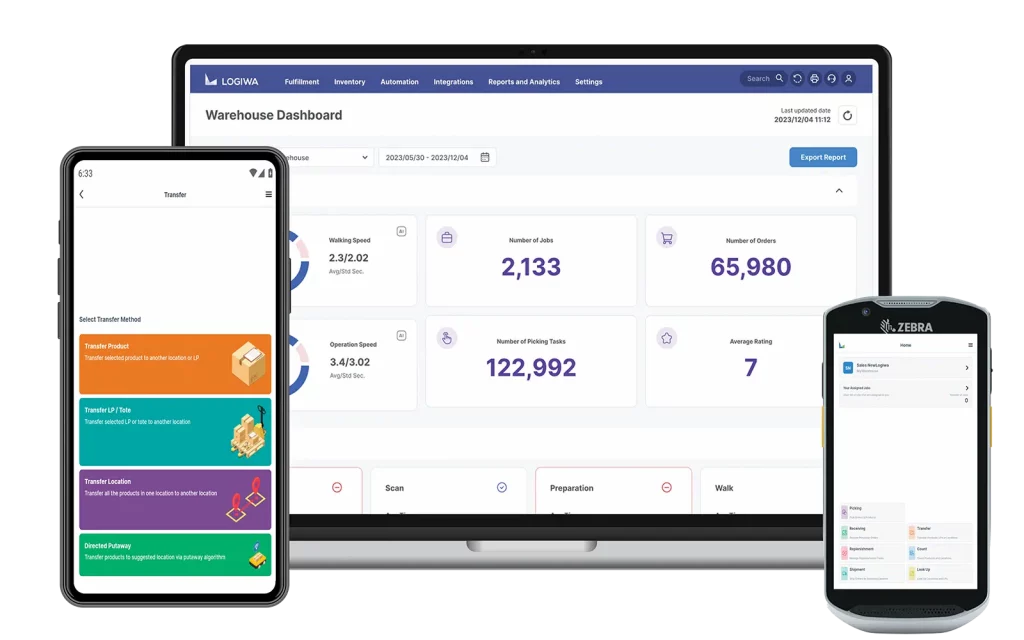

1. Logiwa

Rating: 4.2/5 (G2)

Key Features:

- Real-time inventory visibility and management

- Free connectors for robotics integration

- Optimization of storage space

- Intelligent automation capabilities

- Scalability and flexibility

- Guaranteed 100% system uptime

Logiwa is a cloud-native warehouse management system (WMS) designed to cater to warehouses of varying order volumes, whether low or high. Packed with a plethora of features, Logiwa offers numerous warehouse automation options to streamline operations effectively.

One of its standout features is its array of automation protocols, enabling seamless optimization of storage, picking, packing, documentation, and more. Many Logiwa users have reported significant time savings daily through the implementation of even basic automation rules.

Moreover, Logiwa comes pre-integrated with leading fulfillment partners, including robotic system integrations, allowing users to control and monitor warehouse robotic systems directly from the application. Even if Logiwa lacks a specific integration, users can effortlessly connect their platforms or applications through the system’s API/EDI functionality.

Thanks to its user-friendly interface and high configurability, Logiwa offers swift onboarding, minimizing the time required to realize its value. Its scalability ensures that the platform can adapt seamlessly to evolving business needs and peak periods.

With Logiwa’s cloud-native design and mobile app, users can conveniently monitor and manage warehouse automation remotely. Offering competitive pricing without compromising on value, Logiwa is a prime choice for businesses seeking a cost-effective WMS with reduced professional service fees.

2. Softeon

Rating: 3.5/5 (G2)

Key Features:

- Comprehensive labor, transportation, and order management

- Highly customizable to meet specific business requirements

- Slotting optimization for efficient storage

- Efficient billing management functionalities

Softeon offers a Warehouse Management System (WMS) with Warehouse Execution System (WES) capabilities or a standalone WES that seamlessly integrates with existing WMS solutions to automate warehouse operations effectively. Softeon’s WES software provides numerous opportunities for automation, including automated picking, order batching, resource allocation, billing, and replenishment.

The system offers real-time visibility into throughput, bottlenecks, and other critical events, ensuring warehouse managers stay informed about warehouse operations at all times. Softeon can be deployed as a cloud, on-premise, or hybrid solution, catering to diverse business needs.

The cloud-based solution offers superior scalability and flexibility, allowing businesses to adapt quickly to the evolving demands. On the other hand, the on-premise solution provides enhanced security and control, appealing to organizations with strict data governance requirements. The hybrid solution combines the benefits of both deployment models, offering the best of both worlds in terms of scalability, control, and security.

Learn about 3PL companies here.

3. Fortna

Rating: 3.0/5 (Capterra)

Key Features:

- Integration of robotics and equipment

- 24/7 customer support

- Intuitive web-based user interface

- Real-time control of material-handling equipment

Fortna’s Warehouse Execution System (WES) harnesses the power of cloud technology to enable remote monitoring and control of warehouse processes. This intelligent software offers automation options to optimize order fulfillment operations effectively.

For instance, the WES seamlessly integrates with various warehouse robots such as AGVs, AMRs, AS/RS, and conveyor systems. Once integrated, users can leverage these connected hardware solutions to automate tasks and enhance productivity levels.

Beyond automating machinery, Fortna empowers businesses to optimize their workforce by automating task assignments, picking paths, and more. The system employs science-backed proprietary algorithms to drive improved operational performance, resulting in cost savings and heightened warehouse efficiency.

4. Symbotic

Rating: Not rated

Key Features:

- Automation hardware and software solutions

- Fully scalable capabilities

- Smart tasking, routing, and palletization algorithms

- Advanced mobile robotics controls

Symbotic offers a comprehensive end-to-end solution for automating warehouse operations. Its suite of automation hardware includes autonomous mobile robots and robotic arms designed to efficiently handle tasks such as picking, transporting, and palletizing inventory.

The AI-powered software provided by Symbotic enables centralized control over all physical automation processes. This software can manage a large fleet of warehouse robots simultaneously, ensuring seamless coordination and operation.

Clients have the flexibility to choose between utilizing Symbotic’s AI-powered Warehouse Management System (WMS) to control existing robots or incorporating Symbotic’s hardware with their existing WMS. Symbotic’s solutions seamlessly integrate with a wide range of warehouse systems, offering compatibility and adaptability.

5. Swisslog

Rating: 4.5/5 (Capterra)

Key Features:

- Modular Warehouse Management System (WMS)

- Functionality includes Warehouse Execution System (WES), Warehouse Control System (WCS), and Automation Control System (ACS)

- Cloud-based services for enhanced accessibility

- Business Intelligence tools with user-friendly dashboards

- 24/7 customer support

Swisslog delivers data-driven solutions to automate warehouse and logistics operations. Its SynQ Warehouse Management System (WMS) integrates seamlessly with warehouse machinery, utilizing data insights to develop and implement automation strategies.

In addition to its software offerings, Swisslog collaborates with physical automation suppliers to provide a wide range of automation solutions, including AGVs, conveyor systems, and picking technologies. These systems can be integrated with the SynQ WMS to enable real-time monitoring and control of automated processes.

In summary, Swisslog offers a comprehensive solution for implementing warehouse automation, aimed at reducing overhead costs and enhancing operational performance.

6. Omron

Rating: Not rated

Key Features:

- Ethernet-based machine control network

- All-in-one system for machine and process control

- Open communication and programming standards

- Synchronous machine control

Omron specializes in providing on-premise warehouse automation solutions designed to optimize efficiency and productivity. Its Sysmac Platform facilitates the synchronization of automated machinery, enhancing database connectivity and ensuring smooth execution of warehouse processes like picking, packing, and storage.

Additionally, Omron offers warehouse management and control systems to streamline logistics, inventory management, and customer communications. The solution caters to various industries, including retail and manufacturing, and can be tailored to meet specific warehouse goals and requirements.

7. Dematic

Rating: 4.8/5 (G2)

Key Features:

- Round-the-clock customer support

- Smooth implementation process

- Harnesses artificial intelligence for enhanced performance

- Provides real-time insights through data analytics

Dematic harnesses the power of artificial intelligence and real-time data analytics to execute and optimize warehouse automation processes. By leveraging Dematic’s hardware solutions, including receiving, transport, picking, and storage systems, businesses can streamline their physical operations effectively.

Furthermore, Dematic offers a suite of software tools designed to facilitate warehouse automation and control automated robots. For instance, Dematic Operate enables monitoring and control of single-site operations, while Dematic Connect caters to multi-site automation requirements. By integrating Dematic’s hardware and software with existing Warehouse Management Systems (WMS), users gain full visibility and control over their warehouse operations.

Moreover, Dematic seamlessly integrates with leading warehouse management solutions like Logiwa, providing users with a comprehensive automation ecosystem and enhancing operational efficiency.

8. Locus Robotics

Rating: Not rated

Key Features:

- Multi-language display for enhanced accessibility

- Flexible configuration options to suit diverse needs

- Easily scalable and integratable with existing systems

- Robots as a Service (RaaS) offering for cost-effective deployment

Locus Robotics specializes in automated mobile robots and offers the LocusONE warehouse automation platform, powered by data science. This comprehensive platform facilitates programming, deployment, and monitoring of fleets of automated warehouse robots.

To make warehouse automation more accessible, Locus Robotics offers Robots as a Service (RaaS), a subscription-based program that reduces operational costs and technology barriers associated with deploying automated solutions. This alternative model provides businesses with a flexible and cost-effective approach to implementing automation.

Furthermore, Locus Robotics systems are designed to seamlessly integrate with other solutions, including warehouse management systems like Logiwa. This integration enhances data sharing and optimization capabilities, further improving warehouse operation efficiency.

FAQs on Warehouse Automation System:

How do warehouse automation systems enhance safety?

Warehouse automation systems reduce the need for manual labor in performing potentially hazardous tasks, thereby minimizing the risk of accidents and injuries. By deploying automated solutions, warehouses can create safer working environments and prevent downtime caused by accidents.

How can businesses evaluate the right warehouse automation system for their needs?

Businesses should consider factors such as price, features, scalability, user-friendliness, and compatibility with existing systems when evaluating warehouse automation systems. It’s essential to choose a system that aligns with specific warehouse requirements and can scale with business growth.

What is the Robots as a Service (RaaS) option provided by Locus Robotics?

Robots as a Service (RaaS) is a subscription-based program offered by Locus Robotics, providing businesses with a cost-effective alternative for deploying automated solutions. This model reduces operational costs and technology barriers, making warehouse automation more accessible and affordable.

Can warehouse automation systems integrate with other business systems?

Yes, many warehouse automation systems offer seamless integration with existing business systems, like Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems. This integration enables data sharing and